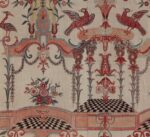

For two millienia, India was the only country that had figured out how to dye or print in color in cotton, because it was extremely difficult before the modern era, involving complicated methods and obscure plant extracts. Pliny marveled over it in 70 A.D. and England didn’t learn the methods until the mid-1700s . So India was more or less the sole supplier of printed cottons, or chintz – a Hindi word – not just to Europe but also to places such as Japan, southeast Asia, and the middle East, in patterns following the local traditions. An exhibition at the St. Louis Art Museum entitled Global Threads: The Art and Fashion of Indian Chintz tells the story.

Click to enlarge

Why is chintz expensive but chintzy means cheap?

Have you ever wondered why chintz is an expensive luxurious fabric for upholstery but chintzy means cheap and tacky? The exhibit tells you. Chit or chimt is a Hindi word meaning variegated and English borrowed it to refer to high-quality colorful printed cottons which were wildly popular in the eighteenth and nineteenth centuries but had to be imported from India until British explorerers and colonists learned the methods. With industrialization in the nineteenth century the popularity of chintz grew and cheap, low-quality imitations first became available. It was at this time, in 1851, that George Eliot wrote in a letter that some fabric she was thinking of buying looked “chintzy”, indicating that people with refined tastes and style were avoiding the cheap copies, and that’s the first known appearance of the word.

Designs for European tastes

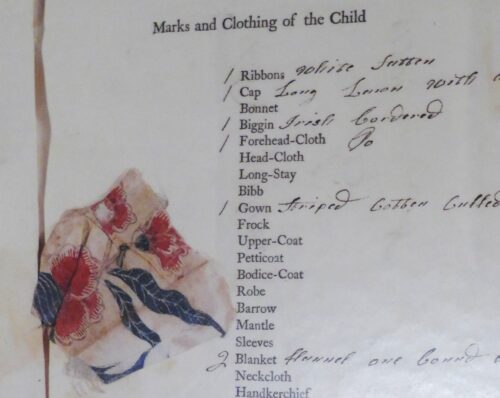

When impoverished mothers left children at Foundling Hospitals in England, they often left a swatch of Indian chintz to later prove kinship, as in this page from a hospital “billet book” from 1759.

Clothing exported from India in the 1700s to England (man’s dressing gown) and a remote Dutch province where chintz was especially popular (woman’s jacket)

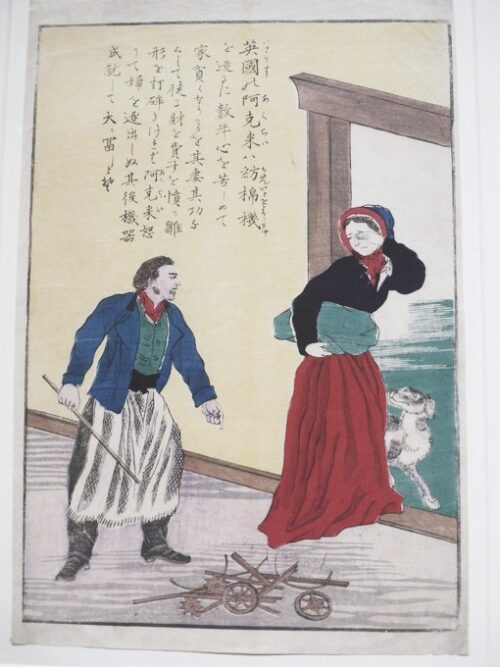

Indian chintz in Japan

Lives of Great People of the Occident was a series of woodblock prints issued by the Japanese Ministry of Education in 1873 to instruct about European inventors. This one shows the time the wife of Sir Richard Arkwright, English inventor of cotton-spinning machinery, destroyed one of his prototypes in anger because he’d been devoting too much time to unprofitable pursuits, and he kicked her out of the house.

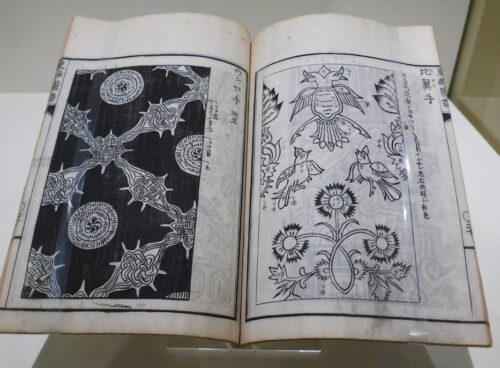

Illustrated Manual of Chintz (1785), published in Japan for collectors of Indian chintz

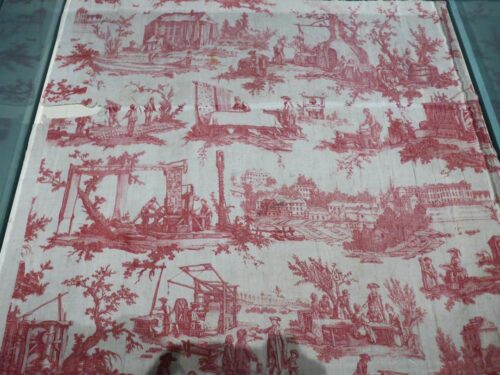

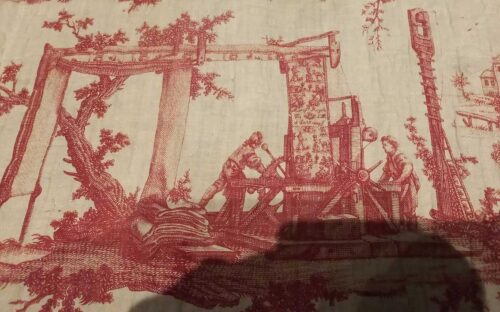

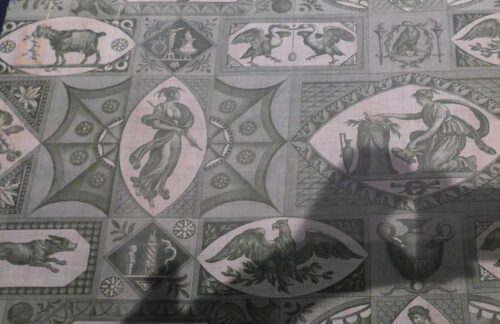

French toiles

Toile (cloth or canvas), or toile de Jouy, means chintz printed with scenes of people, landscapes or animals that became popular in the 18th century. One of France’s centers for it was the town of Jouy. The red one (1783) depicts fifteen or so of the many laborious time-consumg steps in making printed cottons. The green one (1803) is one of the first European textiles ever printed in green which is an especially difficult color to achieve.

Cotton is incredibly difficult to dye

Cotton is very resistant to dying and printing, and apart from that it doesn’t grow well in Europe so it was seldom if ever used for clothes until the sixteenth or seventeenth century. Before that Europe mainly had linen and wool, and silk for the rich. As early as 70 A.D. Pliny was marveling at the complicated and mysterious procedures that existed in the east for dying cotton, and which hardly changed until the development of industrial chemicals in the late nineteenth century.

Without modern chemcials you can’t just dye cotton as we think of dying. You have to dye it with a special dye that will not have the color you want until you apply a fixative called a mordant which transforms the dye into the color you want and fixes it to the fabric. So for example to make a pattern of red flowers you print the flowers using wood blocks and a dye that doesn’t appear red; let’s say it looks blue. Let it dry, then place the whole fabric in a mordant bath. The blue flowers will turn red and then you wash out all the mordant.

Each color requires a different mordant, and this simplified description has ommitted many steps, not the least of which is drying the fabric in the sun for days between each one. A design with five or six colors can involve thirty steps and a couple months of work. Modern chemicals and technology have eliminated all this effort and nowadays just a few artisans carry on the traditional pre-industrial methods.